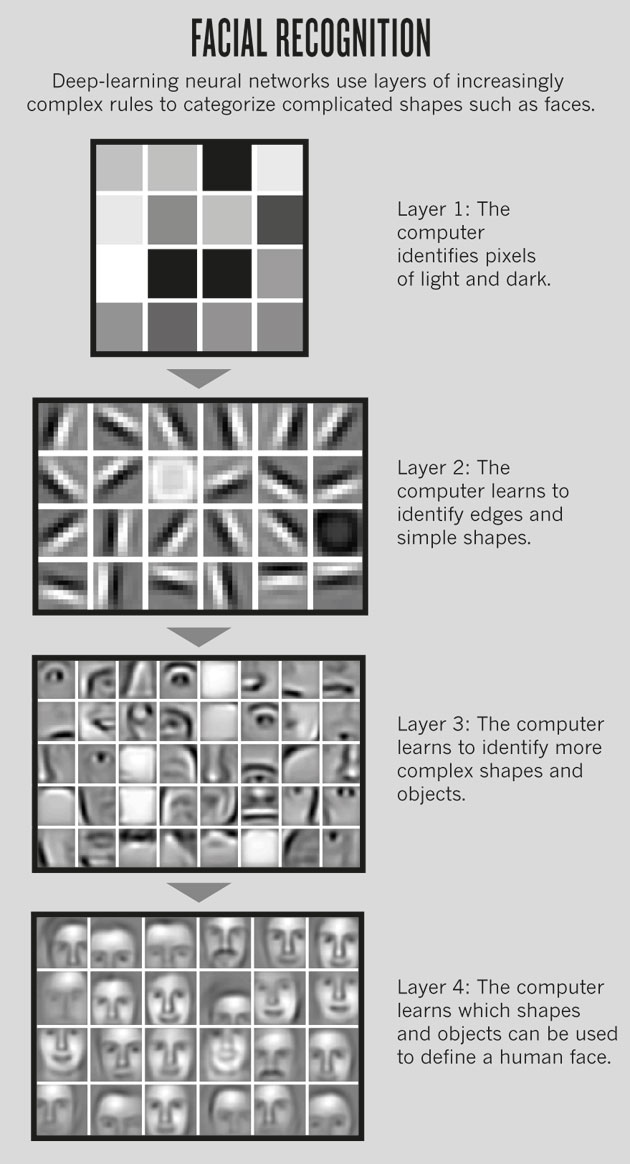

1. The rapidly falling price of parallel computing which lets artificial neural networks (the mechanism behind machine learning) perform multiple operations in parallel. Graphics processing units (GPUs) are examples of neural networks. They can see a pixel of an image in relation to all the pixels around it, and can thus make classifications based on complex patterns. When running in the cloud, GPUs can recognize your friend's face in an image uploaded to Facebook and make millions of 'tag suggestions' a day.

2. Better algorithms, such as a tweak to hierarchical pattern recognition that enabled what we now call deep learning. When this algorithm was applied to Google's online translation service in 2016, its error rate fell by 60% overnight.

3. Big data and a widely available set of data sources. Think of a toddler - the more chairs he sees, the better he'll be at identifiying a chair next time she sees one. A.I. needs exposure to a very large quantity of data to accurately identify patterns, classify inputs and to solve the problem its being trained on.

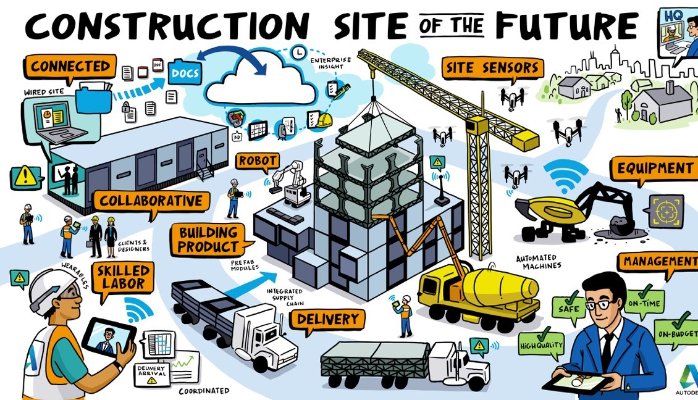

We're not (yet) talking about super-intelligent builder-robots which execute designs generated by algorithms, but even some early explorations of this are underway and could be indicative of future engineering trends. But let's save that discussion for another day.

A.I. for Construction

Nowadays, a construction site manager with a mobile device can quickly capture photos, videos and updates to the latest project conditions (models, drawings, schedules). The latest media and data is uploaded to cloud-platforms, where it can be analyzed at a project or cross-project level. These data-sets will continue to grow exponentially as the cost of drones, laser scanners, wearable cameras and other data collection devices falls, as mobile-apps for construction add functionality, and as technology becomes adopted by more and more project team members.

Smartvid.io lets users upload photos, voice and video recordings to their platform, where their A.I. engine VINNIE then looks at and listens to the media to place smart tags on images and audio. Thanks to this automatic tagging, contractors can later accurately sift through gigabytes of media taken on a typical project to find exactly what they're looking for. In some cases builders can find documentation that protects them against a claim, saving of millions of dollars. It's not just precise, it's quick too. In 2016 Engineering News Record (ENR) hosted their annual photo competition, but this time they partnered with smartvid.io to make sure none of the pictures depicted hazardous safety situations on-site. Alongside human safety experts, VINNIE scanned through the more than 10,000 photos in under 10 minutes - the same task took the human judges over 4.5 hours. What's more, VINNIE correctly identified 10% more photos depicting people than its carbon-based competitors, flagging 32 pictures featuring people not wearing safety helmets and 106 without high-visibility clothing. The safety experts agreed that an AI like this could help them quickly sort and identify on-site safety hazards which require a more careful review.

The availability of software that can automatically sort, filter and extract pertinent features from images strengthens the case for increased onsite photo and video monitoring. Drones, already popular in construction as a way to perform inspections of inaccessible areas, may soon "see" sites as humans haven't been able to, not just from a different angle, but identifying patterns that lead to higher safety risks or impending schedule and cost overruns. And as "smart helmets" such as DAQRI go from prototypes to field-ready devices in the coming years, A.I. image and video recognition tools will assist site inspectors to identify similar hazardous behaviours or conditions in real time.